| Type | stainless steel etch sheet |

| Thickness | 0.3 mm – 3.0 mm |

| Size | 1000*2000, 1219*2438mm, 1219*3048mm,1500*3000mm,Customized |

| SS Grade | 304, 316, 201, 430 etc. |

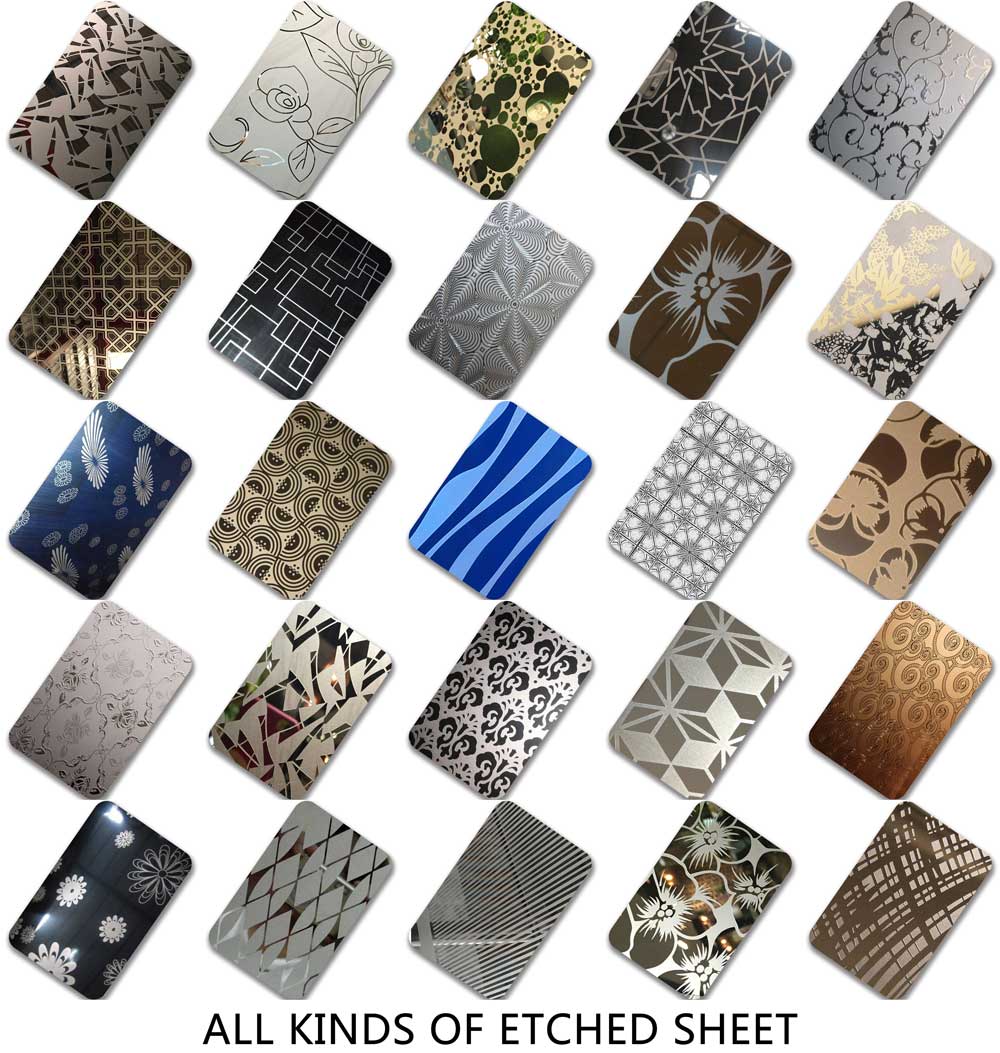

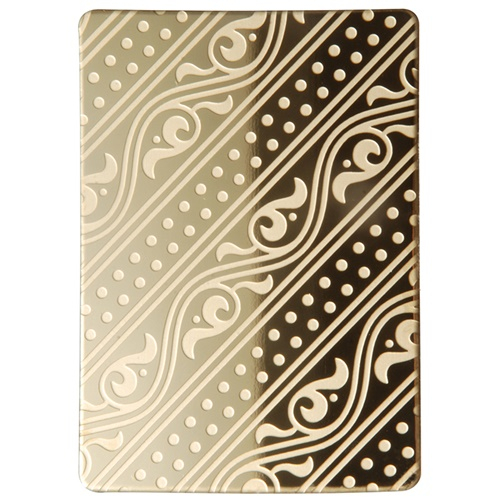

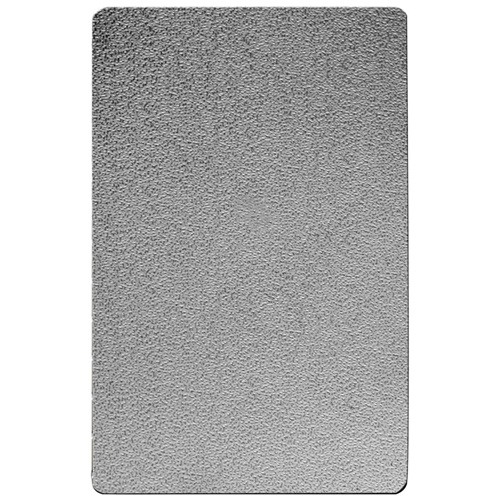

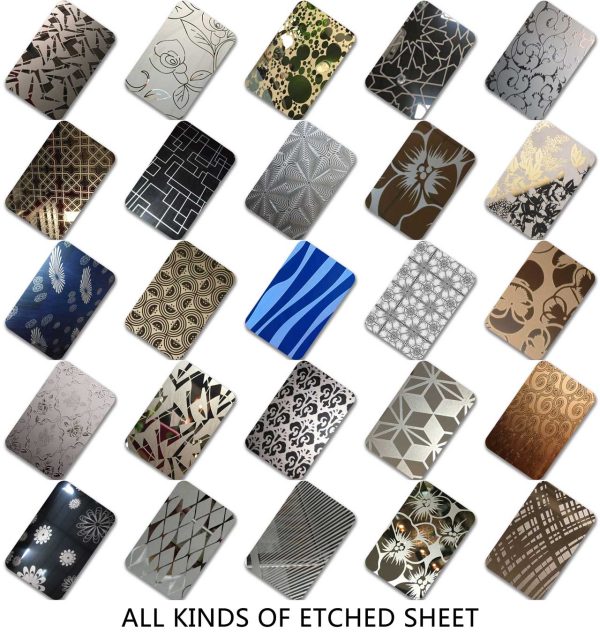

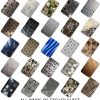

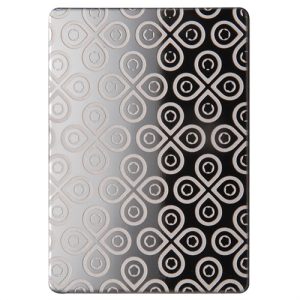

| Finish | NO.4, Mirror, Hairline, Etching,Embossed,Vibration, Sandblast, Combination, lamination |

| Colors | Sliver, Golden, Black, Bule, Green, Purple, Copper, Bronze |

| Origin | POSCO, JISCO, TISCO, LISCO, BAOSTEEL etc. |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

| Application | Construction, Indutry, Building, Chemical, Auto |

| Chemical composition | ||||

| Grade | SUS 304 | SUS 316 | SUS 430 | SUS 201 |

| Elong(10%) | ≥ 40 | ≥40 | ≥ 22 | ≥35 |

| Hardness | ≤90HRB | ≤90HRB | ≤90HRB | ≤101HRB |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60 | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12 | ≤0.08 |

Stainless steel etching plate is used to etch various patterns on the surface of stainless steel by chemical methods. Take the 8K mirror panel, wire drawing plate and sandblasting plate as the base plate. After the etching treatment, the surface of the object is further processed. The stainless steel etching plate can be processed with various complex processes such as local embossing, wire drawing, inlaying, and local titanium. The stainless steel etching plate can achieve the effect of bright and dark patterns and gorgeous colors.

The process flow is:

Stainless steel plate → degreasing → water washing → drying → screen printing → drying → water immersion → etching pattern leaf (sheet) water washing → deinking → water washing → polishing → water washing → coloring → water washing leaf (sheet) hardening treatment → sealing treatment → cleaning leaf (sheet) drying → inspection → product.