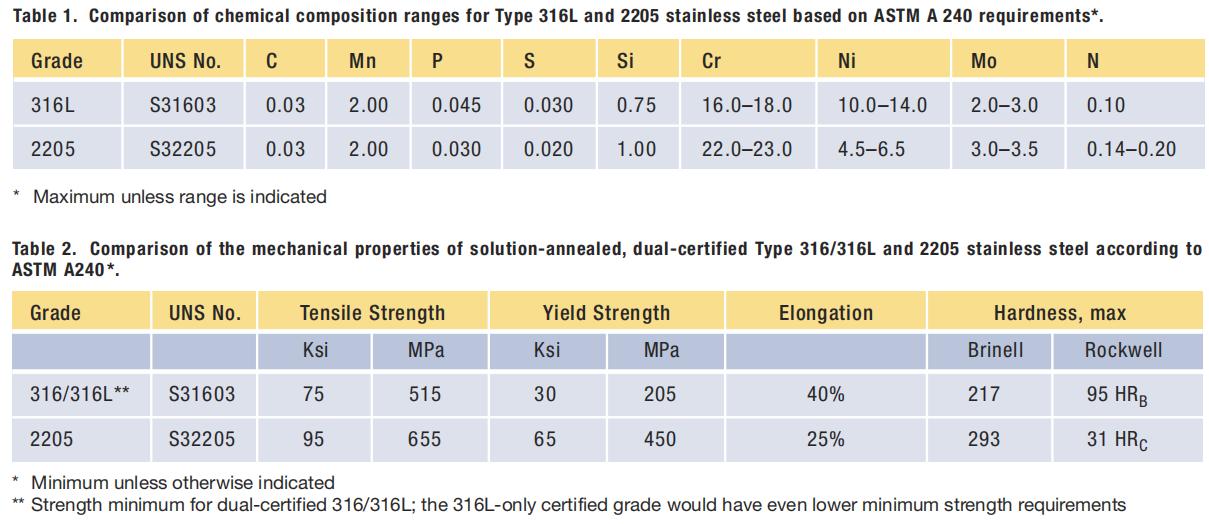

Duplex stainless steel 2205 Standard No.: ASTM A240/A240M-01 Duplex stainless steel 2205 alloy is a duplex stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It has high strength, good impact toughness and good overall and local stress corrosion resistance. The yield strength of 2205 duplex stainless steel is more than twice that of ordinary austenitic stainless steel. This feature enables designers to reduce weight when designing products, making this alloy more price competitive than 316317L. This alloy is particularly suitable for the temperature range of – 50 ° F/+600 ° F.

Application field editor

·Pressure vessels, high-pressure storage tanks, high-pressure pipes, heat exchangers (chemical processing industry).

·Oil and gas pipelines, heat exchanger pipe fittings.

·Sewage treatment system.

·Classifiers, bleaching equipment, storage and treatment systems for pulp and paper industry.

·Rotary shaft, press roll, blade, impeller, etc. in high strength and corrosion resistant environment.

·Cargo box of ship or truck

·Food processing equipment

standard

ASTM/ASME……….. A240 UNS S32205/S31803

EURONORM……….. 1.4462 X2CrNiMoN 22.5.3

AFNOR………………. Z3 CrNi 22.05 AZ

DIN…………………….W. Nr 1.4462

Corrosion resistance

Uniform corrosion

Due to the content of chromium (22%), molybdenum (3%) and nitrogen (0.18%), the corrosion resistance of 2205 is better than that of 316L and 317L in most environments.

Local corrosion resistance

The content of chromium, molybdenum and nitrogen in 2205 duplex stainless steel makes it highly resistant to spot corrosion and crevice corrosion in oxidizing and acidic solutions.

Stress corrosion resistance

The duplex microstructure of stainless steel is helpful to improve the stress corrosion cracking resistance of stainless steel. Under certain temperature, stress, oxygen and chloride, austenitic stainless steel will undergo chloride stress corrosion. Because these conditions are not easy to control, the use of 304L, 316L and 317L is limited in this regard.

Corrosion fatigue resistance

2205 dual-phase steel has high corrosion fatigue strength due to its high strength and corrosion resistance. The processing equipment is vulnerable to corrosion environment and loading cycles, and the characteristics of 2205 are very suitable for such applications.