1. PVD

Process: Color electroplating is carried out in a vacuum environment at a specific temperature and time

Features: Environmental protection, good metal texture, long-lasting and bright color,

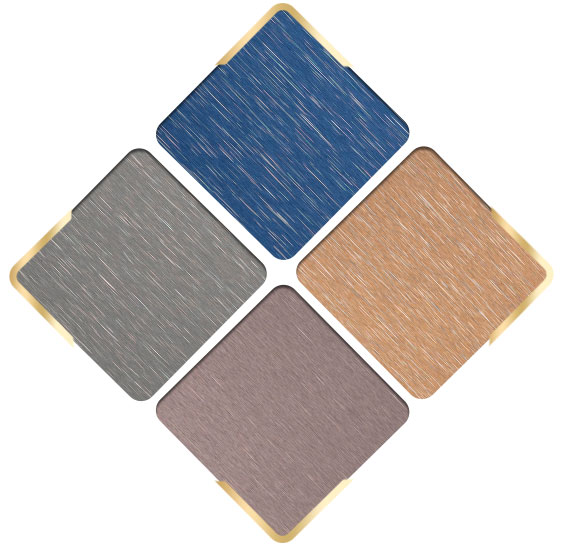

Conventional colors: black titanium, titanium gold, large gold, champagne gold, rose gold, yellow bronze, wine red, brown, coffee, sapphire blue, emerald green, 7 colors, etc

2. Chemical plating

Also known as non electrolytic plating or self catalytic plating, it is a plating method that uses a suitable reducing agent to reduce metal ions in the plating solution to metal and deposit them on the surface of the part without external current.

Process: Electroplating colors in specific solutions

Features: Insufficient environmental friendliness, limited electroplating colors. Conventional electroplating colors include black titanium (with added black), green bronze, red bronze, etc

3. Nano colored oil

Process: The surface is colored with nano colored oil, similar to surface painting

Features: 1. Almost any color can be electroplated, 2. It can be coated with real copper, 3. The metal texture is slightly inferior, and 4. The surface texture is covered by 30%